A few nice prototype manufacturer images I found:

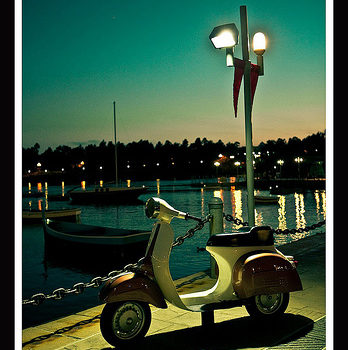

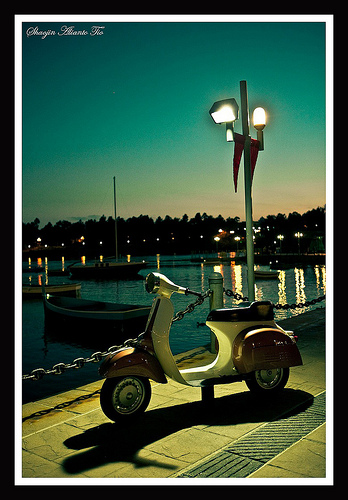

OH!!! Vespa…

Image by Shaojin+AT

Picture: Vespa

Location: Loews Portofino Bay, Orlando

Vespa is an Italian brand of scooter manufactured by Piaggio. The name means wasp in Italian.

The Vespa has evolved from a single model motor scooter manufactured in 1946 by Piaggio & Co. S.p.A. of Pontedera, Italy—to a full line of scooters and one of seven companies today owned by Piaggio—now Europe’s largest manufacturer of two-wheeled vehicles and the world’s fourth largest motorcycle manufacturer by unit sales.[1]

From their inception, Vespa scooters have been known for their painted, pressed steel unibody which combines a complete cowling for the engine (enclosing the engine mechanism and concealing dirt or grease), a flat floorboard (providing foot protection), and a prominent front fairing (providing wind protection) into a structural unit.

History

Vespa 150 TAP, modified by the French military, that incorporated an anti tank weapon

Post World War II Italy, in light of its agreement to cessation of war activities with the Allies, had its aircraft industry severely restricted in both capability and capacity.

Piaggio emerged from the conflict with its Pontedera fighter plane plant demolished by bombing. Italy’s crippled economy and the disastrous state of the roads did not assist in the re-development of the automobile markets. Enrico Piaggio, the son of Piaggio’s founder Rinaldo Piaggio, decided to leave the aeronautical field in order to address Italy’s urgent need for a modern and affordable mode of transportation for the masses.

[edit]Concept

The inspiration for the design of the Vespa dates back to Pre-World War II Cushman scooters made in Nebraska, USA. These olive green scooters were in Italy in large numbers, ordered originally by Washington as field transport for the Paratroops and Marines. The US military had used them to get around Nazi defense tactics of destroying roads and bridges in the Dolomites (a section of the Alps) and the Austrian border areas.

[edit]Design

Piaggio MP5 "Paperino", the initial Piaggio prototype

In 1944, Piaggio engineers Renzo Spolti and Vittorio Casini designed a motorcycle with bodywork fully enclosing the drivetrain and forming a tall splash guard at the front. In addition to the bodywork, the design included handlebar-mounted controls, forced air cooling, wheels of small diameter, and a tall central section that had to be straddled. Officially known as the MP5 ("Moto Piaggio no. 5"), the prototype was nicknamed "Paperino".[2]

Enrico Piaggio was displeased with the MP5, especially the tall central section. He contracted aeronautical engineer Corradino D’Ascanio, to redesign the scooter.[2] D’Ascanio, who had earlier been consulted by Ferdinando Innocenti about scooter design and manufacture, made it immediately known that he hated motorcycles, believing them to be bulky, dirty, and unreliable.[3]

D’Ascanio’s MP6 prototype had its engine mounted beside the rear wheel. The wheel was driven directly from the transmission, eliminating the drive chain and the oil and dirt associated with it. The prototype had a unit spar frame with stress-bearing steel outer panels.[3] These changes allowed the MP6 to have a step-through design without a centre section like that of the MP5 Paperino. The MP6 design also included a single sided front suspension, interchangeable front and rear wheels mounted on stub axles, and a spare wheel. Other features of the MP6 were similar to those on the Paperino, including the handlebar-mounted controls and the enclosed bodywork with the tall front splash guard.[2]

Upon seeing the MP6 for the first time Enrico Piaggio exclaimed: "Sembra una vespa!" ("It resembles a wasp!") Piaggio effectively named his new scooter on the spot.[3][4] Vespa is both Latin and Italian for wasp—derived from the vehicle’s body shape: the thicker rear part connected to the front part by a narrow waist, and the steering rod resembled antennae. The name also refers to the high-pitched noise of the two-stroke engine.[citation needed]

Source from: en.wikipedia.org/wiki/Vespa

Speyer – Technikmuseum Speyer – Fokker VFW 614

Image by Daniel Mennerich

The VFW-Fokker 614 (also VFW 614) was a twin-engined jetliner designed and built in West Germany. It was produced in small numbers by VFW-Fokker in the early- to mid-1970s. It was originally intended as a DC-3 replacement. Its most distinctive feature was that its engines were mounted in pods on pylons above the wing.

The VFW 614 was originally proposed in 1961 by the Entwicklungsring Nord (ERNO) group, comprising Focke-Wulf, Hamburger Flugzeugbau (HFB) and Weser as the E.614, a 36-40 seat aircraft powered by two Lycoming PLF1B-2 turbofans. West German industry was subsequently reorganised and Vereinigte Flugtechnische Werke (VFW) was established at Bremen. Development of what was now the VFW 614 continued.

Although Lycoming abandoned the PLF1, development continued using the Rolls-Royce/SNECMA M45H turbofan, which was developed specially for the VFW 614. In 1968, the project was given the go-ahead,with 80 percent of the backing from the West German Government. Full scale production was approved in 1970, by which time VFW had merged with Fokker (a somewhat unhappy arrangement which lasted for only ten years). Also risk sharing agreements had been concluded with SIAT in Germany, Fairey and SABCA in Belgium and Shorts in the UK. Final assembly of the aircraft would be done in Bremen.

The first of three prototypes flew on July 14, 1971. The aircraft was revealed to be of unconventional configuration, with two quiet, smoke-free, but untested M45H turbofans mounted on pylons above the wings. This arrangement was used to avoid the structural weight penalties of rear mounted engines and the potential ingestion problems of engines mounted under the wings. This allowed a short and sturdy undercarriage, specially suited for operations from poorly prepared runways.

Development of the aircraft was protracted and orders slow to materialise, despite a strong marketing campaign. The situation was not helped by Rolls-Royce’s bankruptcy in 1971 which threatened the supply of engines. Also, the first prototype was lost on 1 February 1972 due to elevator flutter, worsening the order situation. By February 1975 only ten aircraft had been ordered. The first production VFW-614 flew in April 1975 and was delivered to Denmark’s Cimber Air four months later.

Only three airlines and the German Air Force operated new VFW 614s. The aircraft was initially prone to engine problems, and it was too expensive for the small regional airlines for whose needs it was designed. Three aircraft were flown but never delivered, and four airframes were broken up before completion. The programme was officially cancelled in 1977, and the last unsold aircraft flew in July 1978. Most aircraft had been disposed of by 1981, with the manufacturer buying back the aircraft and simultaneously ending support of it. Thereafter, only the German Air Force aircraft remained in service, the last being retired in 1999. The last airworthy VFW 614 was in use with DLR for the Advanced Technologies Testing Aircraft System (ATTAS) project. After being based with DLR in Braunschweig, Germany for many years, this aircraft (registered D-ADAM) was retired in December, 2012 to the Deutsches Museum Flugwerft in Oberschleissheim, Germany.

Berlin – Deutsches Technikmuseum Berlin – Berliner Maschinenbau DR-Baureihe 01.10

Image by Daniel Mennerich

The Deutsche Reichsbahn-Gesellschaft’s BR 01 steam locomotives were the first standardised (Einheitsdampflokomotive) steam express passenger locomotives built by the unified German railway system. They were of 4-6-2 "Pacific" wheel arrangement in the Whyte notation, or 2′C1′ h2 in the UIC classification. The idea of standardisation was that it would reduce maintenance costs; i.e. if a BR 01 whose engine shop was in, say, Berlin broke down in Dresden, instead of having to ship the necessary part from Berlin and take the locomotive out of service, a part from the Dresden shop could be used as all of the engines, parts, and workings were exactly the same and produced nationwide. Thus it was a "standard" product for engine shops.

The firms of AEG and Borsig, who were the main manufacturers of these engines, together with Henschel, Hohenzollern, Krupp and BMAG previously Schwartzkopff, delivered a total of 231 examples of this Einheitsdampflokomotive between 1926 and 1938 for the fast passenger services of the Deutsche Reichsbahn.

To begin with, 10 locomotives of this class were built with two-cylinder engines for comparison purposes alongside a similar batch of 10 engines of their sister Class 02, which had four-cylinder compounding. Extensive measurement and trial runs were conducted, but after lengthy discussions the controversial decision finally fell in favour of the two-cylinder configuration, which was simpler to maintain but less powerful and less economical than the four-cylinder compounds.

The first Class 01 locomotive that went into service was not 01 001, but 01 008, which is preserved today in the Bochum-Dahlhausen Railway Museum. The mass production of Class 01s was somewhat delayed at first because in the 1920s there were neither enough routes with the necessary axle load of 20 tons nor sufficiently large turntables. Not until the beginning of the 1930s did the Class 01 become the predominant express train locomotive of the Deutsche Reichsbahn. By 1938 there were 231 Class 01 locomotives available for the prestigious express train duties. Another 10 four-cylinder Class 02 locomotives (01 111, 01 233–241) were converted to two-cylinder Class 01 models between 1937 to 1942. To accommodate for the many routes with axle load restrictions too low for Class 01 service, in the early 1930s, a third variant was created: the Class 03 designed with a two-cylinder engine and axle load of 18 ton, of which no less than 298 were built. Launched in 1939, the three-cylinder DRG Class 01.10 was a further development of the 01.

A total of five series or batches were delivered, each with minor variations: 01 001–010 (1926), 01 112–076 (1927–28), 01 077–101 (1930–31), 01 102–190 (1934–1936), 01 191–232 (1937–1938).

Even in the 1930s the employment of Class 01s was limited to the relatively few routes that had already been modified to take a 20 ton axle load. From Berlin outwards they were the Anhalt, Lehrte and Hamburg lines. The Berlin City Railway had first to be strengthened by reinforcing the viaduct arches. Up to 1930, the first 90 engines were stationed at the locomotive depots of Essen, Nuremberg, Erfurt P, Berlin Ahb, Hamm, Magdeburg Hbf, Kassel, Hanover, Hamburg Altona, Bebra and Offenburg. From 1931 they were also stabled at Frankfurt (M) 1, Berlin Leb, Braunschweig, Berlin Pog, Schneidemühl, Königsberg, Göttingen P, Paderborn, Dresden Alt, Breslau, Cologne Deutzerfeld, Hof and Halle P.

Originally, the Class 01’s top speed was restricted to 120 km/h. In order to raise this to 130 km/h, the diameter of the leading wheels was changed from its original 850 mm to 1,000 mm on locomotives from operating number 01 102 onwards and brake effort was increased by installing double-sided working of the brake shoes on the coupled wheels and by braking the trailing wheels. The air and feed pumps were located in smokebox recesses behind the large Wagner smoke deflectors, which had been fitted from 01 077 onwards. (Earlier models were also refitted with Wagner type deflectors later). This made access to the pumps for maintenance purposes more difficult and later Einheitsloks had their pumps located in the middle of the vehicle on delivery. The Deutsche Bundesbahn converted their engines to the smaller Witte smoke deflectors and moved the pumps to the running board in the centre of the vehicle. The Deutsche Reichsbahn in East Germany shied away from such major changes to the load distribution, so that only minor modifications in appearance can be seen even in their last years.

From the third series (01 077 et seq.) the boilers were delivered with longer smoke tubes and thus a shorter firebox. All engines originally had a central lock for the smokebox door. The first locomotives had gas lighting on delivery; from 01 010 they had electrical lighting and the last few batches were given a third headlight.

The Class 01s were equipped with 2’2 T 30, 2’2′ T 32 or 2’2′ T 34 tenders. Their coal capacity was 10 tons of stone coal, and the water tank held either 30, 32 or 34 cubic metres of water. The prototype locomotives, 01 001 to 01 010, were supplied with the smaller 2’2 T 30 tenders, because there were not enough large turntables around. Later these tenders were only used if they were absolutely necessary, e.g. in cross-border services with the Netherlands. From the second series (01 012 et seq.) on, the Class 01 was furnished with rivetted 2’2′ T 32 tenders. The welded tenders, class 2’2′ T 34, appeared only by way of exchange (mainly from brand new Class 44) locomotives. Thereafter they were almost the only ones used during the war years and after the Second World War, because they had a larger water capacity.

Class 01 locomotives remained in service with the Deutsche Bundesbahn until 1973. In the DR, they were still working up to the early 1980s, largely in their original state with large smoke deflectors. They were legendary in their last years for hauling the D-Zug services on the Berlin-Dresden route up to autumn 1977. Only when the large Soviet DR Class 132 diesel locomotives arrived, the Class 01 express train locomotives were finally forced out of scheduled services in the GDR after almost 50 years.